ACG – antifouling and anticorrosion systems

Since its foundation in 1947, ACG has been a pioneer in electrochlorination and has become one of the world’s leading suppliers of solutions for the protection of seawater systems and marine structures.

To combat both the proliferation of marine organisms and corrosion, Azienda Chimica Genovese now has four complementary technologies with very low environmental impact:

Electrochloration – Copper/Alu/Iron Ions – Ultrasonique Systems – Impressed current ICCP

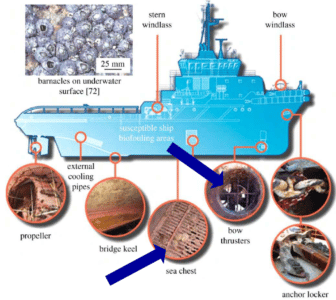

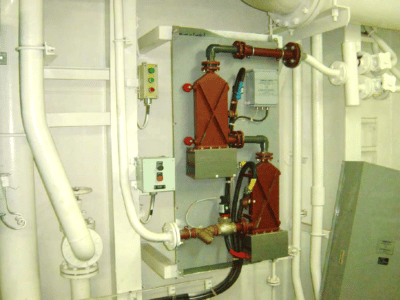

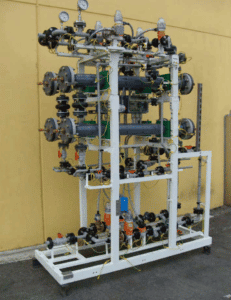

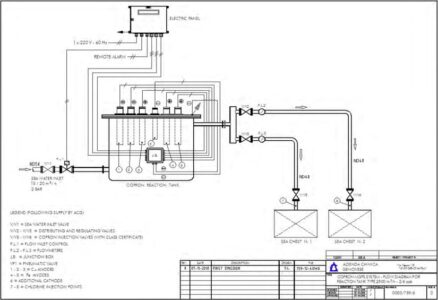

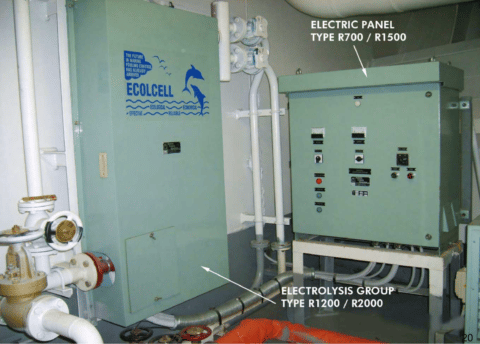

1. ELECTROCHLORINATION: ELCOCELL system

Electrochlorination, of which ACG was a precursor from its creation in 1947, consists of transforming the sodium chloride contained in salt water into sodium hypochlorite, a very effective biocidal and disinfectant “chlorine equivalent”.

The ECOLCELL system fights and eliminates both micro and macro marine organisms in the seawater circuits of ships, platforms, power stations or desalination units at sea or on land.

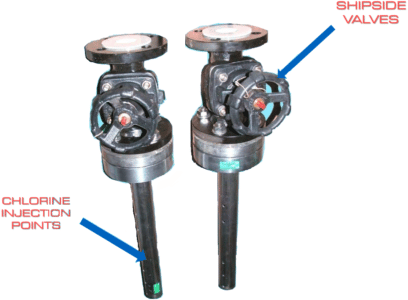

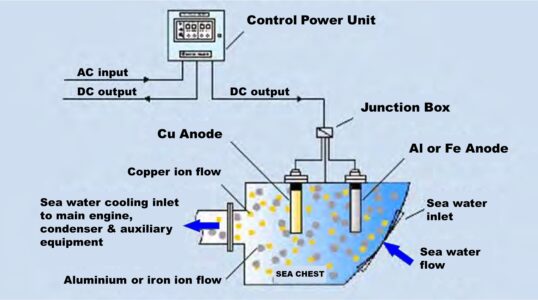

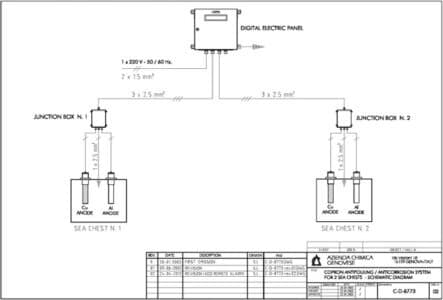

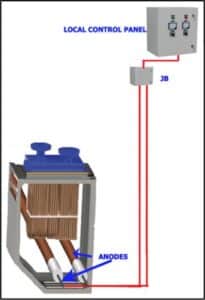

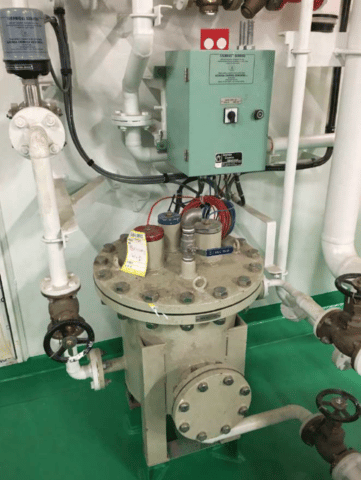

2. COPPER/ALU/IRON IONS: COPRON antifouling and anticorrosion system

COPRON is an antifouling system for the control of macro-organisms (mussels, etc.) by diffusion of a very small quantity of copper ions produced by ionisation of copper anodes.

The COPRON system combines these copper anodes with one or more aluminium anodes or iron/stainless steel anodes to also control pipe corrosion.

It is important to note that the use of copper as a biocide has been under international control for several years as a potential marine pollutant, and its use in EU waters is regulated by ECHA, which authorises some companies to sell this type of system. ACG is listed in Art. 95 of the suppliers authorised to market biocides under Regulation (EU) No. 528/2012.

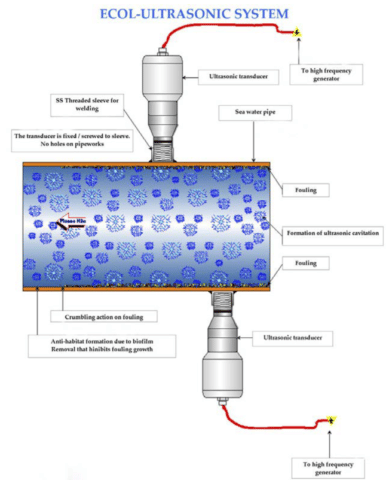

3. ULTRASONIC: ECOL-ULTRASONIC system

New, lower cost methods – less energy consumption, minimal use of chemicals and reduced environmental impact – are constantly being demanded.

To meet this demand, ACG has developed ECOL-ULTRASONIC. This ultrasonic system is very effective in combating micro and macro organisms with clean and economical technology.

The transducers in the seawater circuit create an acoustic cavitation that attacks the biofilm on the pipe walls and loosens it, preventing it from forming again.

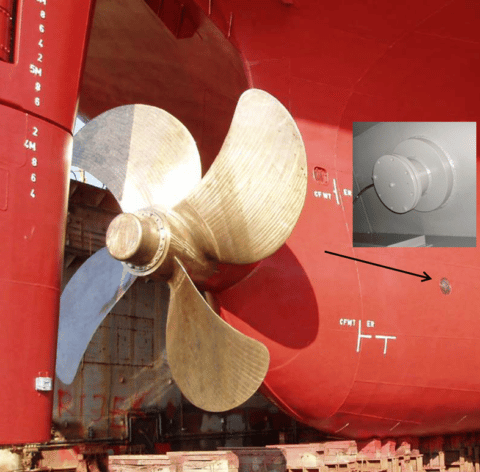

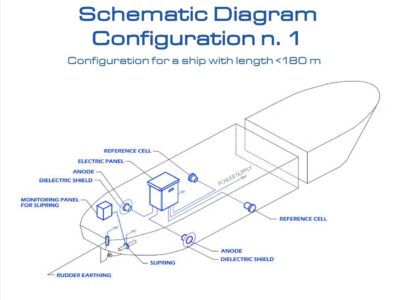

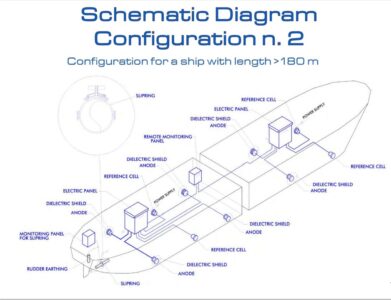

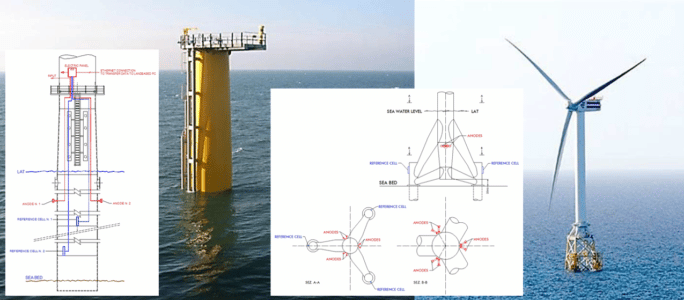

4. IMPRESSED CURRENT: MARIMPRESS device

MARIMPRESS is an impressed current cathodic protection (ICCP) system. It is used to protect ship hulls, floating docks, oil platforms, wind turbines, hydro turbines and all submerged steel structures from corrosion.

The system works by continuously measuring the potential of the submerged steel surface using zinc reference electrodes mounted on the hull (embedded type).

If this potential starts to rise above the pre-set value (220 mV for steel hulls: at higher potentials corrosion will occur), the rectifier supplies the correct amount of direct current required to maintain the pre-set value to the activated titanium anodes mounted on the hull (embedded type). In this way, not only the hull, but when grounded the rudder, propeller, shaft and stabilizer fins are completely protected from corrosion.

The system automatically adjusts the output current to cope with changes in sea water conditions, ship speed or paint condition, all of which can affect the rate of corrosion.

For offshore structures, the intelligent MARIMPRESS WT (ICCP) system can be regulated and controlled remotely from the control room or from land using its own bespoke software. The design of MARIMPRESS WT (ICCP) is based on international standards such as: DNV, Germanischer Lloyd and NACE specifications.