Thordon propeller shaft bearings

Thordon Bearings offers several shaft line bearing system options, each offering specific benefits for different water environments and operating conditions.

Over 2000 water lubricated bearing installations and accumulated bearing wear records continue to prove that Thordon bearings provide the lowest overall life cycle operating costs and increased propulsion system reliability.

Benefits for the shipowner :

- Excellent operational and wear performance

- Zero risk of pollution

- Reduced shaft seal maintenance costs (no back seal)

- Easy to maintain

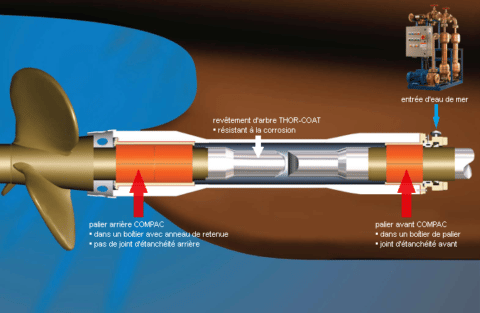

Thordon COMPAC is a high performance water lubricated bearing system primarily for “clear water” operation.

Specially formulated with a low coefficient of friction to reduce start-up friction and eliminate chatter, COMPAC’s unique configuration is designed for rapid hydrodynamic film formation at low rpm.

Thordon has an extensive reference list of COMPACs fitted to passenger ships, ferries, tankers, bulk carriers and other military vessels.

Thordon SXL is designed to offer increased resistance to abrasive particle wear and longer life in water slightly more abrasive than clear water.

SXL offers a low coefficient of friction for reduced starting torque and smooth operation at low speeds.

SXL bearings can be found, for example, on vessels that frequently operate in coastal waters and at low speeds, such as large yachts or service vessels.

Thordon Composite / RiverTough is specially formulated to provide superior life in highly abrasive water conditions such as inland rivers.

Thordon Composite bearings operate in combination with a hard coated nickel-chromium-boron liner exceeding the life of rubber bearings by a ratio of two or more.

Over 15 years experience on hundreds of pushers operating in the muddy waters of the Mississippi in the USA confirms actual wear of between 0.25mm-0.38mm per year.